Shenzhen City Industrial Co., Ltd. Contact: Liu Jinrong Fixed: 075529966071

Mobile: 13510810460

Fax: 075529966073

Address: 5th Floor, Building 3, Guangyu Industrial Park, Xixiang Street, Baoan District, Shenzhen

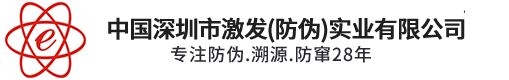

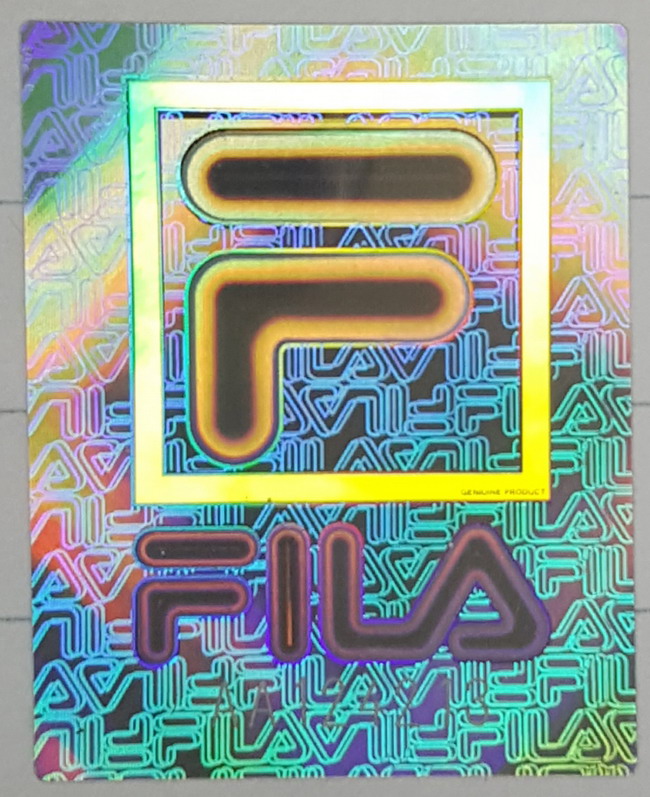

Holographic laser anti-counterfeiting is divided into two types: laser marking and paper marking.

Holographic laser anti-counterfeiting, also known as laser anti-counterfeiting, its technology includes laser holographic image anti-counterfeiting, encrypted laser holographic image anti-counterfeiting and laser lithography anti-counterfeiting technology. Its main products are anti-counterfeiting film and anti-counterfeiting paper. Specifically, the anti-counterfeiting film can be subdivided into laser holographic anti-counterfeiting transfer film and composite film. The anti-counterfeiting paper can be subdivided into laser holographic anti-counterfeit transfer paper and laminated film.

The upstream raw materials required for the laser holographic anti-counterfeiting film are the original film, the base paper, the paint, etc., wherein the original film and the base paper account for a relatively high proportion of production cost. The original film belongs to petrochemical products and is affected by the international oil price. Pulp is the basic raw material of the paper industry, but the lack of forest resources has led to a large amount of pulp imports in China. Therefore, changes in global petroleum and pulp prices and changes in supply and demand affect the purchase price of raw materials such as raw film and base paper, which in turn affects the manufacturing costs of holographic anti-counterfeiting products.

Laser holography has a small proportion in all current laser technology applications, but holographic technology is closely related to our lives, such as anti-counterfeiting trademarks for medicine, food, light industrial products, cosmetics, bank securities, etc. Holographic images, stereoscopic movies, VR, AR, exhibitions, etc., also have important applications in military reconnaissance and scientific research.

The downstream of holographic anti-counterfeiting labels includes public security and anti-counterfeiting, packaging materials, new energy and other fields. The packaging materials market has the largest scale and the most demanding, and the most significant impact. For daily consumer goods manufacturers such as cigarettes, alcohol, cosmetics, pharmaceuticals, food, etc., in order to cope with the increasingly fierce market competition, the packaging design of products has become more and more important. The colorful packaging can attract customers, stimulate customers' desire to purchase, and promote product sales. At the same time, enterprises can also print various complex patterns and photochromic information in packaging to enhance the anti-counterfeiting performance of products. In addition, in the fields of new energy and new materials, the holographic optical anti-counterfeiting product manufacturing technology is used to form a nano-deep-grain structure on the surface of the solar cell, which can reduce the reflection effect and improve the energy conversion efficiency.

Based on such a downstream background, more and more products choose laser holographic packaging to replace the original ordinary packaging, and the market size of other holographic optical anti-counterfeiting products manufacturing industries will also expand rapidly. As the market demand continues to increase and the application field continues to expand, in the next few years, the upgrading of downstream packaging materials will provide a broader development space for holographic optical anti-counterfeiting products manufacturers.

On the whole, due to the huge demand in the downstream market, the prospect of laser holographic anti-counterfeiting products is broad, but the fluctuation of upstream raw material prices has a greater impact on industry costs. For enterprises, when upstream costs rise, attention should be paid to production efficiency and quality to ensure a pass rate to reduce unnecessary costs. When the upstream cost is at a normal level, the development and upgrade of laser holography technology can bring more profit margins and open up wider application fields in the downstream market.

Previous: Cosmetic security labels