Shenzhen City Industrial Co., Ltd. Contact: Liu Jinrong Fixed: 075529966071

Mobile: 13510810460

Fax: 075529966073

Address: 5th Floor, Building 3, Guangyu Industrial Park, Xixiang Street, Baoan District, Shenzhen

Application of micro-scale aluminum film in laser anti-counterfeiting labels

Application of micro-scale aluminum film in laser anti-counterfeiting labels

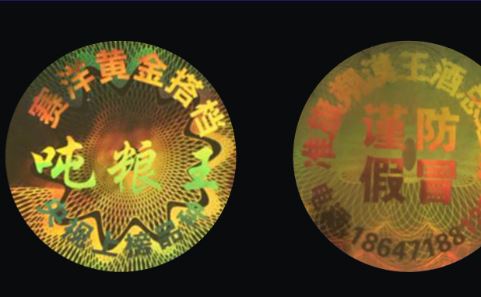

we all knowLaser security labelIt uses the combination of embossing copy technology and laser holography to enhance the anti-counterfeiting effect through processes such as flower clusters and latent images. Laser anti-counterfeiting labels pay more attention to the choice of materials. Generally, there are aluminum film, high-reflection film and composite film. Different materials have different characteristics. Different manufacturers choose different materials for anti-counterfeiting laser labels. Some are due to cost considerations. For the consideration of the production process, today we will understand the application of micro-scale aluminum film in laser anti-counterfeiting labels.

The micro-scale aluminum film used in the laser anti-counterfeiting label is turned into a thin film through a chemical reaction of self-oxidation, and then used on the label. There are two commonly used schemes. One is to place the printed text or logo under the aluminum film. The production process is to add electrolytic solution to the aluminum film for oxidation, so that people can see the original under the aluminum film. The text or logo. Pay attention to the use of this material when making laser anti-counterfeiting labels, because this process is irreversible. The anti-counterfeiting phenomenon can only be used once. This is a direct oxidation mode, which can be applied to many laser anti-counterfeiting labels. Another anti-counterfeiting solution is to print the polymer solution with salt before the two motors, print the corresponding text or logo in the middle of the aluminum film, and connect the two electrodes after it dries. When this scheme is applied to anti-counterfeiting laser labels, it is relatively convenient. When the protective film is removed during use, the moisture in the air will be absorbed by the hydrophilic substance of the label to form an electrolyte solution, which causes the oxidized part to form corresponding text and Logo. However, when this scheme is applied to laser anti-counterfeiting labels, the display time for text and logo is relatively short.

The above is a description of the use of micro-scale aluminum film in laser anti-counterfeiting labels. Through the description, we know two aluminum film oxidation schemes. Both schemes are irreversible after being applied to the anti-counterfeiting laser mark, and the anti-counterfeiting phenomenon can only be used once. Different oxidation methods of aluminum film will affect the production process of laser anti-counterfeiting labels, and the display of anti-counterfeiting effects will be different. It requires continuous technical research to optimize the oxidation scheme and make its application in laser anti-counterfeiting labels smoother. We can also get some inspiration from the application of this aluminum film. Many seemingly useless materials can also be used in laser anti-counterfeiting labels through chemical changes.

Related News

- Is there a tag security tag that can't be torn down?

- Food Information Security QR Code Development Trend

- What are the applications of QR code anti-counterfeit labels?

- What is the printing process of anti-counterfeiting label factory packaging?

- QR Code anti-counterfeiting label becomes the new trend of market anti-counterfeiting traceability

- How do consumers identify laser security labels?

- Introduction to laser holographic anti-counterfeiting knowledge

- How to identify the authenticity of laser anti-counterfeit labels

- Anti-counterfeit QR code label production process

- Laser anti-counterfeiting label production process introduction

- Explanation of laser anti-counterfeiting label aluminum film material

- Laser anti-counterfeiting label based on anti-counterfeiting material anti-transfer technology

- Overview of nanocrystal laser anti-counterfeiting labels

- Explanation of nano-cellulose laser anti-counterfeiting label

- The value of anti-static laser anti-counterfeiting labels

- Overview of the exploration of West Lake Longjing laser anti-counterfeiting labels

- Discussion on Anti-counterfeit Laser Mark Die-cutting Knife

- Overview of layered anti-transfer technology of laser anti-counterfeiting label materials

- Description of laser anti-counterfeiting label manufacturing process

- Reasons for the confusion in the pesticide laser anti-counterfeiting label market